Making cabinets with your own hands, important points

Currently, many rural residents cannot afford to buy new furniture for their home. And city apartments do not always have a large area where it would be possible to place household items. But, despite this, the people nevertheless learned to cope with these problems on their own. To do this, you can make a wooden cabinet with your own hands, without the services of specialists. To carry out such a design at home is not particularly difficult, but in order for the furniture to have a long operational period, it is necessary to familiarize yourself with the sequence and nuances of the work in advance.

What is needed for manufacturing

Today, the consumer market provides various wooden materials for the manufacture of household items. Therefore, before starting to consider such a question as how to make a cabinet yourself, you first need to decide what material it will be made of. According to experts, the best products for these works are:

- plywood - this multilayer material has high wear resistance and strength. In addition, due to environmental friendliness, it is absolutely harmless to human health. Plywood is produced with solid plates, which simplifies the process of assembling household items;

- wood chipboards - sheets made of chipboard are considered the most popular products for creating home furniture. This is due to the fact that they combine good quality at an affordable price. These products are resistant to changes in temperature and moisture, do not deform under the influence of an aggressive environment and are characterized by increased strength;

- solid wood boards - the material from the boards is cut from different types of wood. They are produced in different sizes, certain types of processing and the quality of carpentry. For the construction of furniture, mainly boards made of pine, birch and oak are selected. These rocks are endowed with high strength and resistance to changes in temperature and humidity.

Installation of household items from a pine tree with your own hands is a laborious process, since the breed is not solid enough. But when choosing this material, it will be possible to create an extravagant design in any room.

Wooden boards

Wooden boards Chipboard

Chipboard Plywood

PlywoodSo, having considered the options of materials that will be needed for the manufacture of furniture, it is also worth familiarizing yourself with the tools for performing work. The manufacture of cabinets is performed by the following equipment:

- hand saw for sawing wood;

- grinder for polishing a wood surface;

- goniometer, for measuring the angle of inclination;

- ruler or meter tape measure for measuring dimensions;

- wooden dowels, for fastening products and filling;

- metal corners for fastening furniture designs;

- joiner plate, for the manufacture of shelving;

- mastic to seal the structure.

In addition, in order to revive the household item with the desired shade, it will be necessary to purchase water-based acrylic paint.

Nuances of work, taking into account the type of construction

You can build a wooden cabinet yourself in several ways.

Case

As can be seen from the photo, cabinet furniture consists of several constituent elements, so it is also commonly called modular. A feature of such a cabinet is that the owners can optionally supplement it with various internal and external elements. Initially, the design of the product is designed so that all the details are combined with each other and the body. For the construction of the hull, the presence of elements such as the roof, bottom, rear and side walls will be required. All these elements can be made in the form of removable straight shelves on which things will be located. In addition, it will be possible to build a drawer for shoes.

Preparing grooves for mounting shelves

Preparing grooves for mounting shelves It is better to assemble the structure in a horizontal position

It is better to assemble the structure in a horizontal position We fix the upper bar last

We fix the upper bar last Vertical faceplates

Vertical faceplatesBuilt in

A distinctive feature of the built-in cabinet is that it can be made from improvised materials. The fact is that it is mainly installed in niches of a room or in those places where it is not possible to arrange standard furniture. For the construction of the cabinet does not require a one-piece housing. It may not have one or more walls that are replaced by the floor, ceiling or walls of the building. Filling elements, as a rule, can be made in the same way as cabinet furniture. But having designed such a cabinet with his own hands from improvised materials, the consumer should be prepared for the fact that, unlike the cabinet product, this furniture can not be moved to another place.

The design of each cabinet requires not only the presence of the body and internal filling, but also the front part. The main element of the facade is the door.

In the manufacture of the built-in cabinet, it is important to correctly place the space for future shelves

In the manufacture of the built-in cabinet, it is important to correctly place the space for future shelves Shelves must be attached securely

Shelves must be attached securely Special lags are necessary for fastening doors

Special lags are necessary for fastening doorsDoor fastening

Today, the consumer market offers various systems for fastening furniture doors. Each element has its own specific purpose, which depends on the methods of opening the cabinet.

Swing

Swing doors are the most common type of furniture design. It consists of a wooden canvas and equipment for fasteners. The number of paintings for the cabinet depends on the number of internal sections. As a rule, if the cabinet has one common section, two shutters will be required. If the furniture will consist of one narrow and one wide section, respectively, three sashes will be required. The production of door fastening is carried out on the side walls of the cabinet using the following hinges:

- detachable - this mount is installed on the inside of the cabinet wall;

- universal - these products can be installed regardless of the sides of the cabinet. Hinges are attached simultaneously to the cabinet and furniture doors.

After the hinges are fixed on the product box, doors are hung on them.

Hole preparation

Hole preparation Alignment and installation of loops

Alignment and installation of loops

Coupe

Sliding doors are a sliding system where, when opening a cabinet, one door enters another. Installation of this design requires certain knowledge and skills, therefore, before installing a sliding wardrobe of plywood with your own hands, you first need to familiarize yourself with the name of the components and their location.

Accessories kit includes:

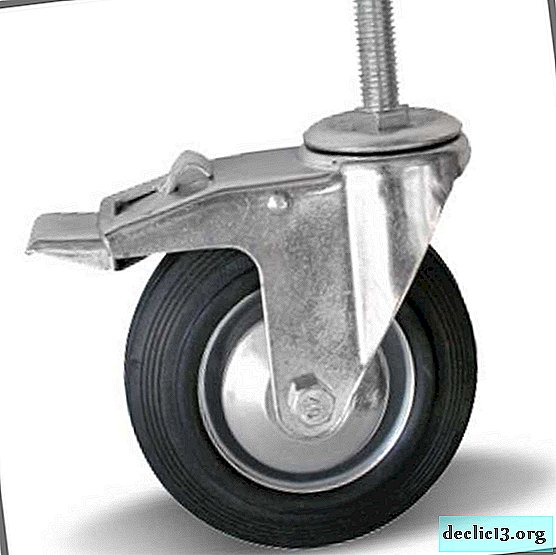

- special wheels for moving doors are installed in the upper and lower parts;

- upper suspension structure, for guiding the paintings;

- the lower guide structure along which the door wheels will move in the grooves;

- cartridges for installation of a wooden cloth;

- locks and door closers for easy door opening.

This design is intended for cabinet furniture with a threshold. If the built-in cabinet will be mounted, it will be possible not to install lower guiding elements on the floor.

Layout and drawings

Before making a cabinet out of the lining with your own hands, you first need to make a markup of its location in the room and draw up a design drawing. Such preliminary procedures will help to quickly assemble cabinet or built-in furniture.

In the layout of the cabinet, it is necessary to take into account its width and height. To do this, first, the estimated installation location is measured with a tape measure. When conducting measurement work, it is important to consider the distance from skirting boards, window sills, pipelines and connectors for connecting electrical appliances. If you miss these points from view, the wooden cabinet may not fit in the designated place, or in the future there may be obstacles when opening the doors or approaching the power source.

For a cabinet, do-it-yourself drawings can be created using an automated CAD program or by hand. In the first case, the cabinet diagram is compiled by a special computer system, in the second embodiment, the cabinet drawings are made by hand. As practice has shown, the second option is simpler, so it is chosen more often. To create a freehand drawing, you will need a sheet of paper and a pencil. Further on the sheet are drawn sketches of the cabinet.

Description of the drawing of a wooden product:

- front view of the cabinet - this sketch includes the width and height of the furniture, the height of the base, the size of the sections, the distance between the shelves. When drawing up a drawing, it is important to consider the thickness of the walls of the furniture and its filling. You also need to specify the mounting points of shelves and doors;

- top and side view - in this case, the depth of furniture and shelves is applied to a sheet of paper. When drawing depth values, it is important to consider the fastening of the doors. So that the shelves do not interfere with the installation of fastening equipment, they should be located at a distance of 10 cm from the edge of the front wall of the furniture. Also on this sketch you need to specify the rounding of the shelves with a radius of - R.

In addition to the indicated values of the furniture body, on the sheet of paper you need to draw the dimensions of the filling elements. Shelves can be made of different configurations and thicknesses, but they must have the appropriate size.

Parts manufacturing

Having made a drawing of the cabinet structure with your own hands and having prepared the appropriate equipment, it will be possible to start manufacturing its parts. To do this, the dimensions of the furniture elements are transferred to a sheet of chipboard using a meter and a pencil:

- the upper part of the cabinet in quantity - 1 pc;

- side walls in an amount of 2 pcs;

- bottom in quantity - 1 pc;

- back wall in quantity - 1 pc;

- furniture shelves in the amount of individual consumer preferences.

Next, with the help of a saw along the planned lines, the phased cutting of parts begins. When performing these works, it is necessary to take into account the thickness of the saw itself, otherwise the furniture elements after sawing will have a smaller size.

After the parts are ready, they must be faced with a melamine film. To do this, a film is applied to the structural elements, which is then ironed. After the lining is set on the details, all of its excess remains are cut off with a clerical knife.

Parts preparation

Parts preparation Edge fixing

Edge fixingAssembly

Cabinet assembly is best done at the intended location. In this case, it will be possible to prevent the deformation of the walls and floor of the room when carrying finished furniture. Initially, cardboard sheets are laid on the intended floor, on which the product structure will be successively assembled.

A step-by-step instruction for assembling the cabinet is carried out in stages:

- the first side sheet is on the floor;

- fasteners are vertically fixed to connect the lower and upper sides of the cabinet;

- the top and bottom of the furniture are installed and fixed on the sides;

- the second side sheet of the cabinet is located and fixed on top;

- the strength of the fasteners is checked;

- the cabinet is turned over by the front side to the floor;

- the furniture back is stacked and fixed;

- the cabinet rises, fits tightly to the wall, in the designated place.

Further, using the level, it is necessary to create an even position of the cabinet, after which the doors should be fastened, as well as the filling set.

So, having familiarized yourself with how to make a cabinet with your own hands, many beginners will not make blunders when designing a structure. A step-by-step guide to manufacturing will help to correctly execute furniture details. And subject to the above assembly sequence, wooden cabinets can stand without deformation for more than a dozen years.